Photo by Brian Butler

Every minute of the day brings the potential for a machinery rescue response. Think about it, how many vehicle extrications are there in the U.S. every single day? How many rings are cut off by rescue companies and emergency room personnel every single day? How many kids get their fingers stuck in toys, bicycle parts, or their head stuck between railings every single day? If we put vehicle extrication aside, many common machinery rescues are minor extrications, disentanglement, disassembles, cutting, lubing, or simply repositioning someone out of a pinch. But think about all the potential entrapment, pin, crush, and stuck limb incidents that can happen in your response area.

Photo by Brian Butler: Old vertical baler compactor in a Trenton NJ warehouse.

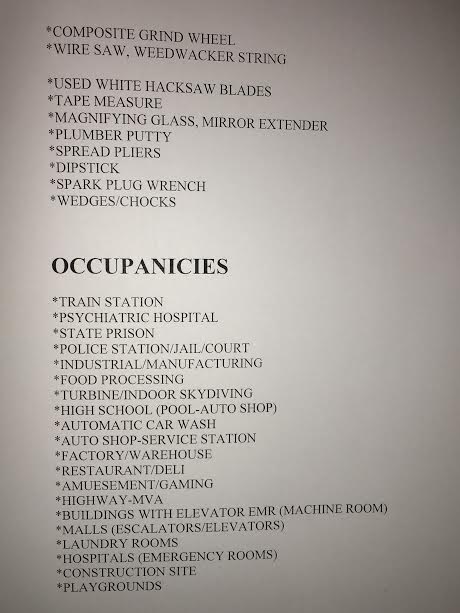

Machinery responses can involve trains, elevators, escalators, industrial, manufacturing plant machinery, conveyor belts, commercial kitchens, amusement parks, car washes, correctional facilities, auto shops, hospitals, appliances, food processing plants, and fitness centers to name a few. Have you ever thought about accidents that could possibly happen that would require a machinery rescue response? How many people are operating ATV's (all terrain vehicles) snow blowers, presses, slicers, grinders, construction and agricultural equipment in your response area?

Believe it, the potential is there!

Photo by Brian Butler: Trenton Transit Station. Kids clothing or limbs caught in escalators can have deadly results, and will require extrication, and disassembly.

After attending a "Man vs Machinery" class at the New York State Technical Rescue Conference, put on by PL Vulcan Training it took no less than a week to put together a well-equipped machinery tool box. They are relatively inexpensive to put together and each kit should be equipped for the type of response area it will serve. Urban areas will differ from rural areas (agriculture vs industrial). The tool boxes are great for practicing skills like removal and cutting of rings, meat grinders, pvc pipe, railings, or fishing stuck fingers out of fuel fillers. The training and use of numerous tools and tricks of the trade make firemen more creative when it comes to thinking outside the box, which can contribute to a successful rescue someday.

You never know when a freak accident will happen on your watch. Every firefighter should highly consider attending a "Man vs Machine" training day.

Photo by Brian Butler: NY Technical Rescue Conference, Montour Falls NY "Man vs Machine"

Below is a machinery tool box and a compiled list of potential accidents and incidents just waiting to happen, including types of occupancies where they might occur. It should make one realize that it's very possible that the machinery tool box will eventually be utilized, or utilized again. (Photos by Brian Butler)

Above photos by Brian Buler

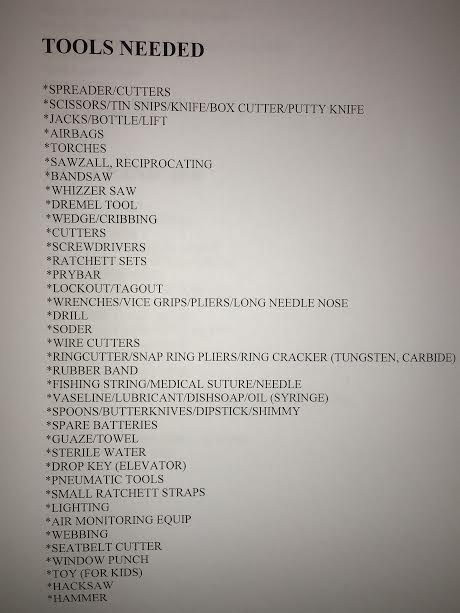

Below: A list of tools to consider when creating a machinery kit:

Tools (continued) and occupancies where accidents might occur.

As you can see, the potential is there for these high risk/low frequency incidents.

MURPHY'S LAW: Imagine a scenario where a single truck company is dispatched for a stalled elevator. Upon arrival, the company officer notices the elevator is stuck on the 7th floor. He sends the low man up to the penthouse to secure the power and makes his way up to floor seven. The low man enters the roof area and hears loud screaming coming from the elevator machine room. Upon opening the penthouse door, he sees an elevator repairman with his arm caught in the drive sheave of a traction elevator.

This is most likely an amputation at best, and a serious machinery accident. This fireman has been to over 50 elevator calls, but didn’t expect this. Having knowledge of elevators and machinery rescue may help with initial actions in this particular scenario. Power shutdown, stabilizing (chocking), requesting additional resources, medics, rescue company, building maintenance, elevator engineer and disassembly comes to mind immediately. If his tool belt/box is present, it may have the tools needed to take apart the drive machine around his arm once movement and power secure.

(Of course safety features and precautions used when repairing elevators have come a long way since the 1980's, but this has happened before.)

The point here is, you never know!

For more on machinery rescue, visit PL Vulcan Training Concepts.

Views: 5021

Comment

© 2025 Created by fireeng.

Powered by

![]()

You need to be a member of Fire Engineering Training Community to add comments!

Join Fire Engineering Training Community